Problem Solving using the 5 Whys

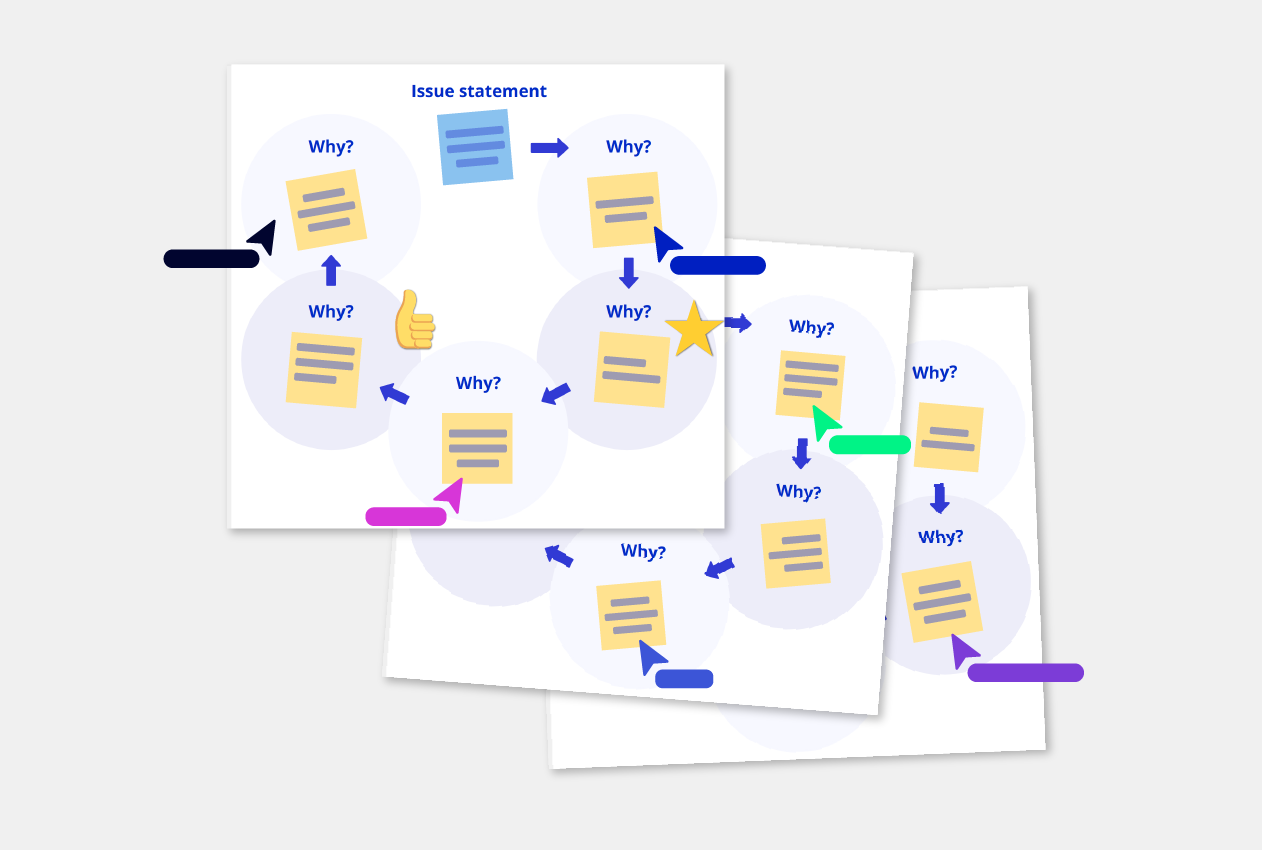

The 5 Whys template is a simple, yet powerful tool used for root cause analysis. Based on the technique developed by Sakichi Toyoda, it takes an iterative approach to problem-solving. Starting with an initial problem statement, a question beginning with ‘why’ is asked 5 times in order to zero in on the root cause.

Along with the Fishbone Diagram, the 5 Whys template is a seminal technique for problem-solving through a deeper understanding of causal relationships. Let us understand this method in a little more detail. Or directly use the template.

What is the 5 Whys root cause analysis?

The 5 Whys problem-solving method was originally developed for Toyota Motor Corporation’s production facility. The technique starts with a single problem and asks a ‘why’ question based on the answer to the previous question.

The iterative process of asking ‘why’ ensures that each step is logically connected to the previous by a cause and effect relationship. Each ‘why’ takes you one step closer to finding the root cause.

5 Whys analysis in six sigma

Six sigma is all about waste reduction, process optimization and quality improvements. The simplicity of the 5 Whys method lends itself well to the analysis stage of six sigmas. Since the technique eschews complex statistical methods, individuals from across functions and departments can participate in the process. It’s a great technique for driving process improvements and ensuring past mistakes do not reoccur.

How to use the 5 Whys template

Since a 5 Whys session is in essence a brainstorming session, it is important to work with a whiteboard and sticky notes. Mapping out the process on an online whiteboard helps people better visualize what happened. Multiple stakeholders can work on Conceptboard’s collaborative template in real time and add their ideas on digital sticky notes. The template is completely editable.

Steps to using the 5 whys template

- Asking the right question – Before you embark on a 5 whys analysis, it is important to start with the right question. Here, a problem statement template can come in handy.

- Gather the right people – All key stakeholders and especially decision makers should be involved in the session.

- Assign a moderator– It is important for the moderator to drive the conversation, ensure each of the steps are followed and assumptions avoided

- Prepare the board in advance – Load the template by clicking the ‘+’ button and choosing ‘Insert template’. Drag and drop the 5 Whys template and share the board with the team.

- Add sticky notes and write down your comments for each round of the process.

- Once the analysis is complete, identify the action points and export the board as a PDF or print it out.

5 Whys Example

Here’s an example of the 5 Whys process and the solutions that came up from the analysis.

- Why was the hospital’s new health care app delayed by 4 weeks?

Answer: Additional complexities were revealed in the testing phase. - Why did additional difficulties come up?

Answer: The creation phase did not include a solution for a major use case. - Why did the creation phase miss a major use case?

Answer: The original brainstorming sessions did not include employees from the department. - Why were key employees missing from the brainstorming sessions?

Answer: The brainstorming session was led by a particular department. In this case, additional departments were brought in later in the development process. - Why is this process managed by a particular department?

Answer: This is how it’s always been done.

Solutions found:

Create a new process that builds on the strengths of all departments and encourages interdepartmental collaboration. Ensure key employees from every department are present in all brainstorming sessions throughout all phases.

If you’ve like this template, we’ve also rounded up 15 of our favourite brainstorming techniques and templates that help you generate new ideas and drive innovation. For additional problem-solving templates, you can use our A3 problem-solving template. Also check out our list of retrospective ideas and templates you can use today with your team.